Online test equipment and training demos

As more people are working from home to reduce non-essential travel, our technical sales engineers can provide online equipment demos or training sessions via web-based video calls.

If possible, send in your own samples and our sales team will be able to present your own products being tested.

Get in touch to discuss your requirements and to arrange an online demo or training session.

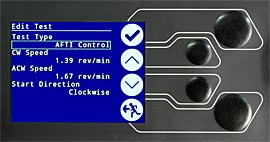

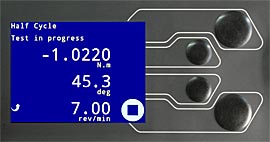

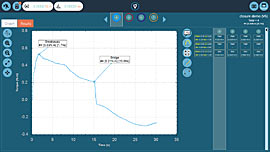

Clear, colour display, with continuous live readings, indication of status, rotational speed, angle, and (with AFTI connected) torque.

Clear, colour display, with continuous live readings, indication of status, rotational speed, angle, and (with AFTI connected) torque.

The AFTI interacts with the Vortex-dV to receive, store and transmit torque data, capture first and ultimate peak values, with pass/fail indicator, and can be used to set control limits for the Vortex-dV. (Order separately).

The AFTI interacts with the Vortex-dV to receive, store and transmit torque data, capture first and ultimate peak values, with pass/fail indicator, and can be used to set control limits for the Vortex-dV. (Order separately). Connect to a PC with VectorPro™ Lite software, for:

Connect to a PC with VectorPro™ Lite software, for:

Run sophisticated routines for closure system product development and design optimisation.

Run sophisticated routines for closure system product development and design optimisation.

For TE closures, Vortex has the sensitivity to detect:

For TE closures, Vortex has the sensitivity to detect:

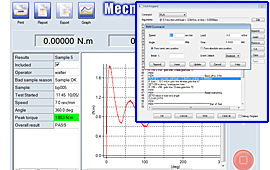

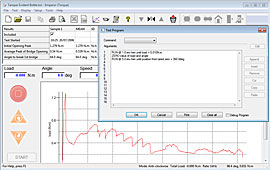

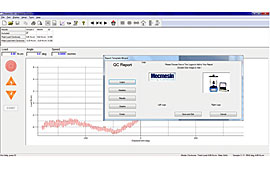

When further evaluation of results is required, a range of calculations are available to help pinpoint areas of interest, for example to accurately differentiate between the breakaway torque peak and the tamper evident band breakage event. Standard and customisable report templates enable easy documentation creation, which can be stored and exported to Microsoft Excel® and SPC packages.

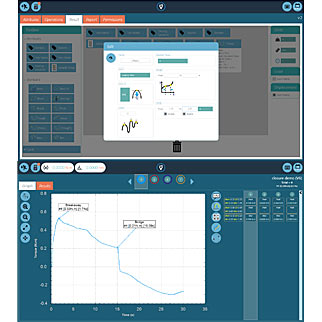

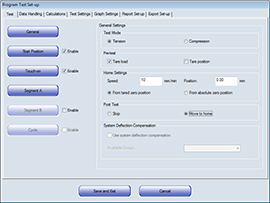

When further evaluation of results is required, a range of calculations are available to help pinpoint areas of interest, for example to accurately differentiate between the breakaway torque peak and the tamper evident band breakage event. Standard and customisable report templates enable easy documentation creation, which can be stored and exported to Microsoft Excel® and SPC packages. Console Mode allows tests to be created very simply by selecting options from radio-buttons and drop-down boxes. A number of pre-configured calculations are available and can be included by simply clicking with the mouse. Console mode is ideal for use on the factory floor by operators who need only minimal training to load and run programs directly from one of the five “Favourite” buttons.

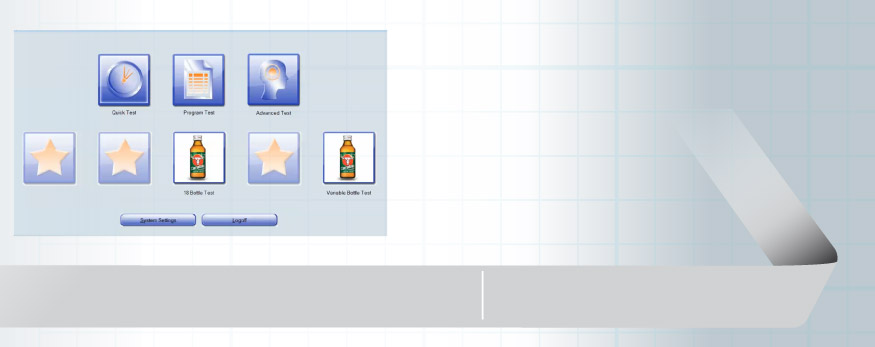

Console Mode allows tests to be created very simply by selecting options from radio-buttons and drop-down boxes. A number of pre-configured calculations are available and can be included by simply clicking with the mouse. Console mode is ideal for use on the factory floor by operators who need only minimal training to load and run programs directly from one of the five “Favourite” buttons.

The keypad is designed to make testing as simple and quick as possible.

The keypad is designed to make testing as simple and quick as possible. Results are shown clearly on the display with additional functions including; audible and visual alarms, memory up to 500 readings and option to export results for further evaluation.

Results are shown clearly on the display with additional functions including; audible and visual alarms, memory up to 500 readings and option to export results for further evaluation. Cam-operated fixture jaws, used for cork extraction tests, are designed to hold the cork securely in place, without pinching it.

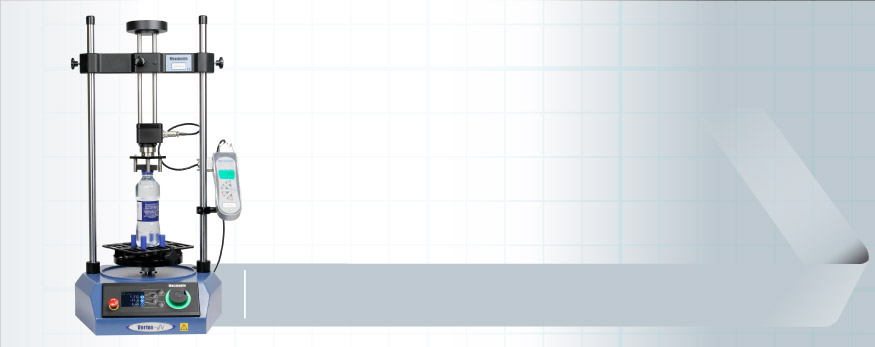

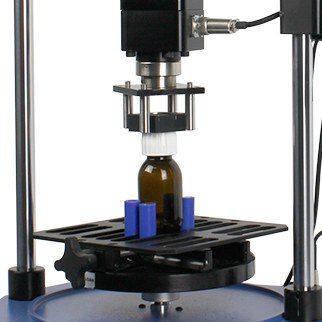

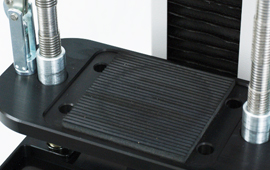

Cam-operated fixture jaws, used for cork extraction tests, are designed to hold the cork securely in place, without pinching it. The bottle cradle uses a non-slip surface, ensuring bottles stay in the correct position.

The bottle cradle uses a non-slip surface, ensuring bottles stay in the correct position. This system is designed to ensure protection from spillage, including a drip tray located beneath the test area, and is CE marked to European standards.

This system is designed to ensure protection from spillage, including a drip tray located beneath the test area, and is CE marked to European standards.

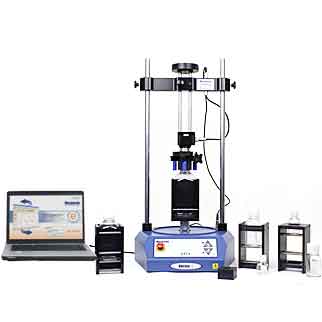

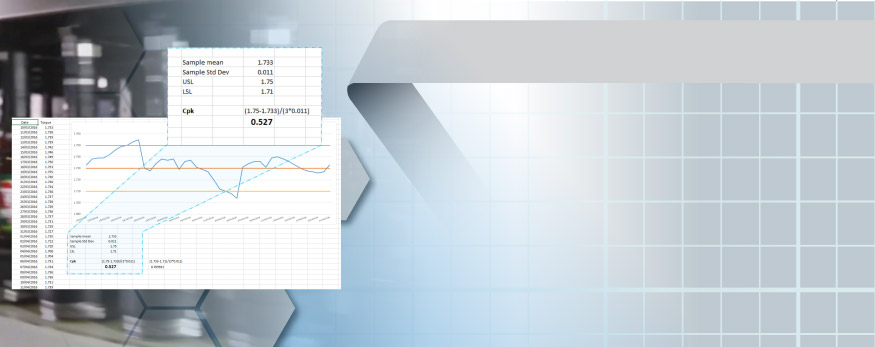

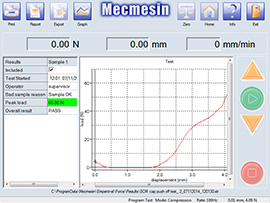

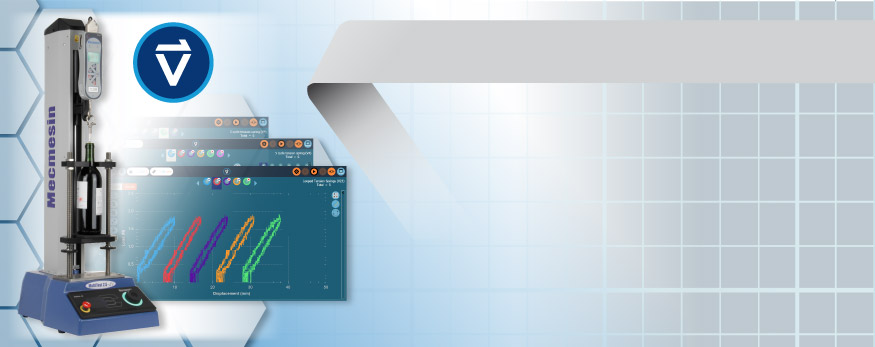

Mecmesin MultiTest-xt universal testers are designed for use directly within the manufacturing environment. The software controls the system, tracks the test sample, the batch and the operator, and captures the detail you require. It performs calculations on the stored results, and interfaces with SPC systems and other analytical packages. Minimal training is required, to begin quick, accurate and repeatable quality-conformance testing on the production line. With the press of a couple of buttons, sample throughput is maximised, while clear colour-coded pass/fail indicators show instant results. A MultiTest-xt system provides rapid feedback to the production line, reducing wastage and guaranteeing closure performance.

Mecmesin MultiTest-xt universal testers are designed for use directly within the manufacturing environment. The software controls the system, tracks the test sample, the batch and the operator, and captures the detail you require. It performs calculations on the stored results, and interfaces with SPC systems and other analytical packages. Minimal training is required, to begin quick, accurate and repeatable quality-conformance testing on the production line. With the press of a couple of buttons, sample throughput is maximised, while clear colour-coded pass/fail indicators show instant results. A MultiTest-xt system provides rapid feedback to the production line, reducing wastage and guaranteeing closure performance. Test selection includes push-button icons for instant access to your five most frequently used tests. You define the button images and the tests as required, while other tests are easy to find by touch menus. The MultiTest-xt range makes routine quality testing simple.

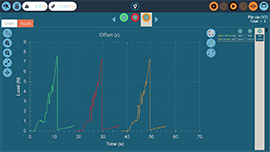

Test selection includes push-button icons for instant access to your five most frequently used tests. You define the button images and the tests as required, while other tests are easy to find by touch menus. The MultiTest-xt range makes routine quality testing simple. You set the criteria: colour-coded pass/fail indicators then identify good and bad test samples. See each test progress as a ‘live event’ graph, in order to observe changes in sample performance, or view a batch in tabulated form for comparisons between each sample.

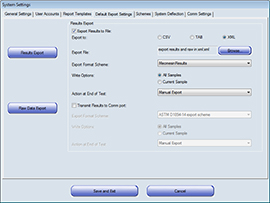

You set the criteria: colour-coded pass/fail indicators then identify good and bad test samples. See each test progress as a ‘live event’ graph, in order to observe changes in sample performance, or view a batch in tabulated form for comparisons between each sample. Use a wide range of calculations to evaluate your test results, and to highlight points of interest. Create your own custom report templates or use those provided as standard. Alternatively, send raw data or calculated results for analysis and use in other systems or applications.

Use a wide range of calculations to evaluate your test results, and to highlight points of interest. Create your own custom report templates or use those provided as standard. Alternatively, send raw data or calculated results for analysis and use in other systems or applications. You can create and store unlimited test programs in your own library, developing and adapting them as your requirements change. A MultiTest-xt selected for its tensile testing capabilities is always tomorrow’s compression tester too.

You can create and store unlimited test programs in your own library, developing and adapting them as your requirements change. A MultiTest-xt selected for its tensile testing capabilities is always tomorrow’s compression tester too. The Emperor™-xt software behind each MultiTest-xt enables export of data direct to an SPC system, a remote PC, printer or datalogger, for further detailed analysis and reporting.

The Emperor™-xt software behind each MultiTest-xt enables export of data direct to an SPC system, a remote PC, printer or datalogger, for further detailed analysis and reporting.

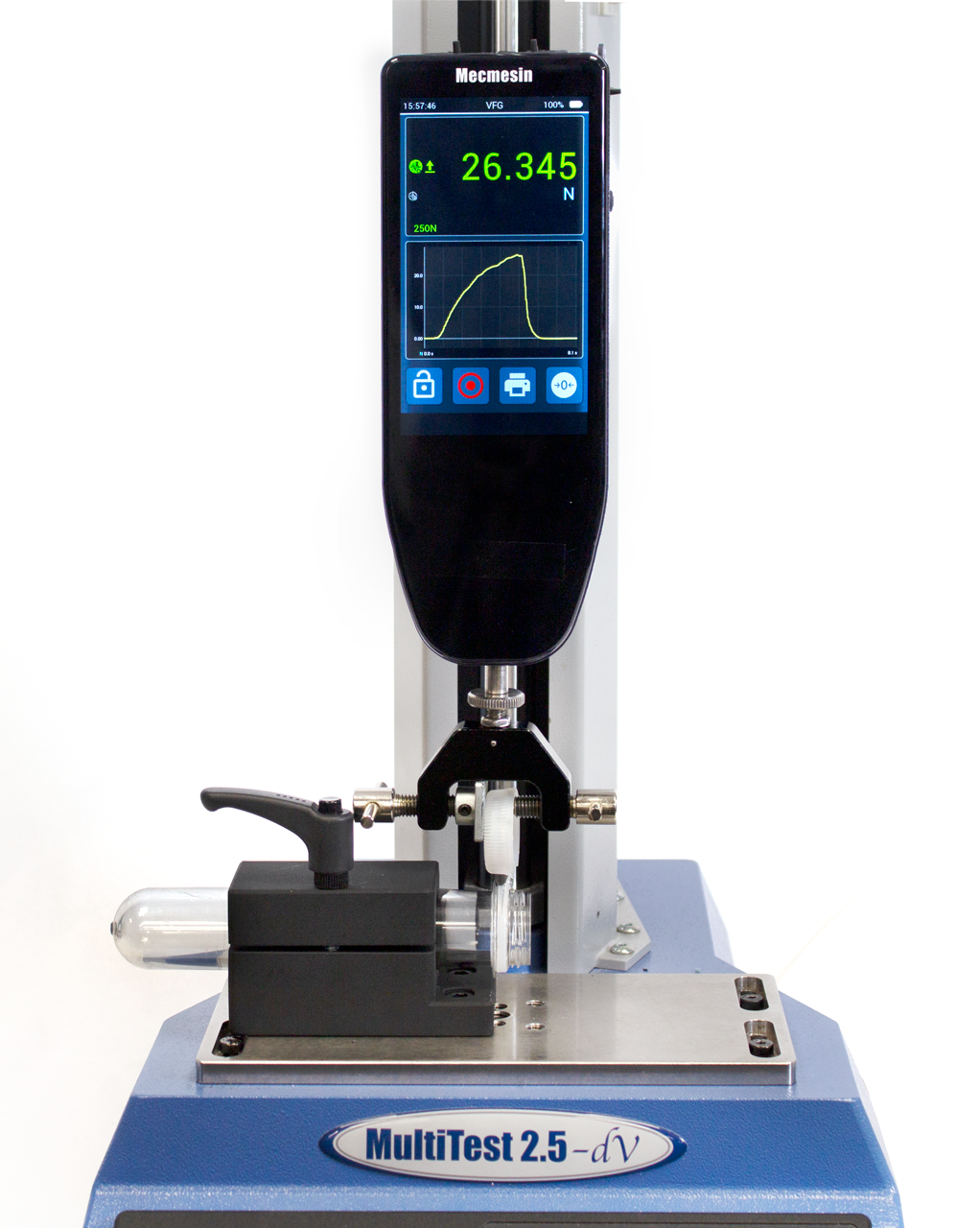

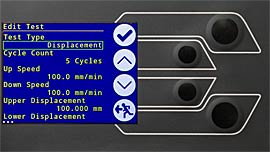

Clear, colour display, with continuous live readings, indication of status, up and down speed, displacement, and (with a gauge connected) load.

Clear, colour display, with continuous live readings, indication of status, up and down speed, displacement, and (with a gauge connected) load. The VFG interacts with the MultiTest-dV to enable controlled testing to a load limit or break. (Order your gauge separately).

The VFG interacts with the MultiTest-dV to enable controlled testing to a load limit or break. (Order your gauge separately). Connect to a PC with VectorPro™ Lite software, for:

Connect to a PC with VectorPro™ Lite software, for:

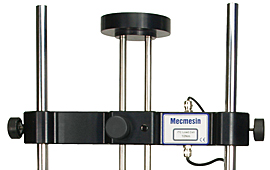

Load tray for applying a predefined axial load e.g. when push-off twist testing child-resistant closures.

Load tray for applying a predefined axial load e.g. when push-off twist testing child-resistant closures. Counterbalance capability for eliminating the weight of a grip being applied to a sample. Significant when testing precise torque at low forces.

Counterbalance capability for eliminating the weight of a grip being applied to a sample. Significant when testing precise torque at low forces.