Error message

Warning: file_get_contents(http://ipinfo.io/3.12.34.211/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).Specification

Cork extraction strength is mostly used in the development of uncorking solutions for Champagne and sparkling wines. It is critical to measure the extraction force of corks in order to maintain a balance between easy opening of bottles by consumers, whilst avoiding exploding corks.

When you wish to make multiple measurements, manual instruments can be too restrictive. Operators performing multiple tests may become fatigued, increasing the risk of injury through improper handling of the sample.

Solution

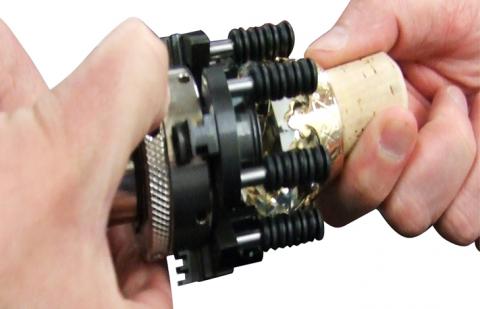

The partnership between the technical and research teams from Mecmesin and Oeneo Bouchage helped to develop the Combi Cork Extraction Tester, specially designed in order to test sparkling wine corks. The Combi Cork Tester provides mechanical accuracy and is used to optimise extraction force measurement with three main advantages;

System

The CombiCork Extraction Tester includes:

The Combi Cork Extraction Tester helped us to simplify measurements because it is easy to set up. This system provides consistent reproducible and safe measurements, without any risk of injury to the operator. Therefore, we can establish valuable opening torque specifications, which are currently used for quality control measurements and development of new products.