Error message

Warning: file_get_contents(http://ipinfo.io/18.223.241.221/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).Versatile and affordable closure torque tester

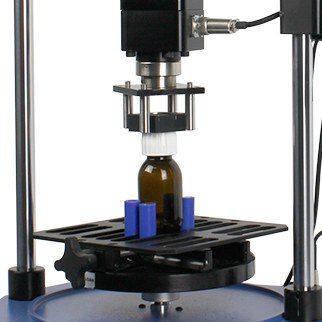

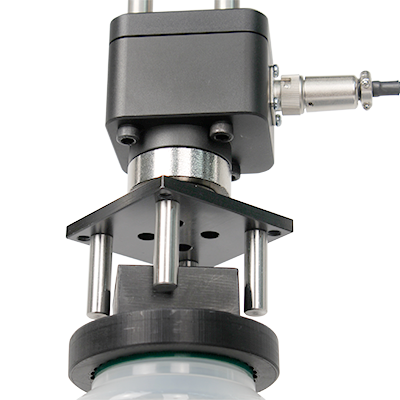

The Vortex-dV is a precision-controlled motorised stand with a choice of torque transducers, an AFTI digital torque display and data capture unit, and a range of grips and fixtures. This robust and simple to use system is suited to either R&D in the laboratory, or quality control in the production area. It improves greatly on manual units with accurate gripping and precise speed control, and in batch testing, eliminates user repetitive strain injury.

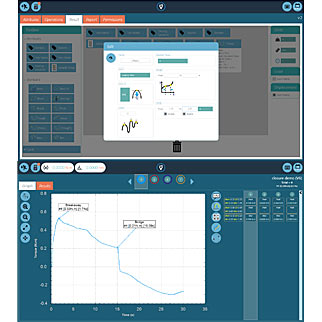

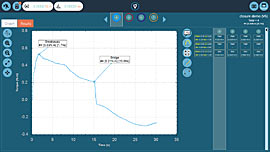

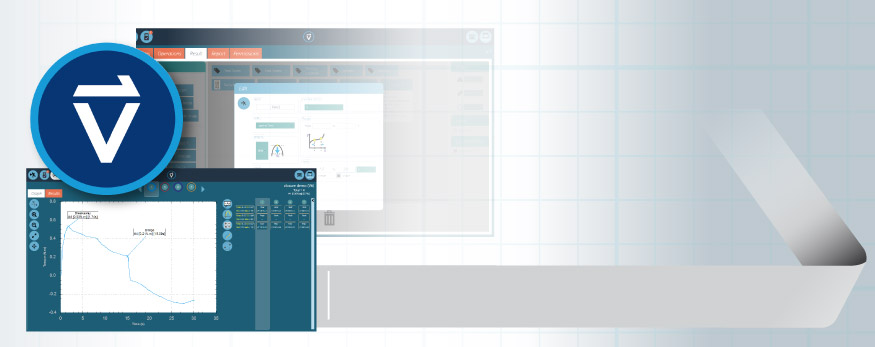

Add VectorPro™ Lite software to a Vortex-dV with AFG, for data acquisition and analysis, and storage of regular test routines.

The AFTI interacts with the Vortex-dV to receive, store and transmit torque data, capture first and ultimate peak values, with pass/fail indicator, and can be used to set control limits for the Vortex-dV. (Order separately).

The AFTI interacts with the Vortex-dV to receive, store and transmit torque data, capture first and ultimate peak values, with pass/fail indicator, and can be used to set control limits for the Vortex-dV. (Order separately).

Connect to a PC with VectorPro™ Lite software, for:

Connect to a PC with VectorPro™ Lite software, for:

* with upper and lower mounting table fitted

Contact Mecmesin

Got a question about this product?

Our technical sales engineers can help find the right solution for your testing requirements and provide online equipment demos with your samples.

Accessories for this System

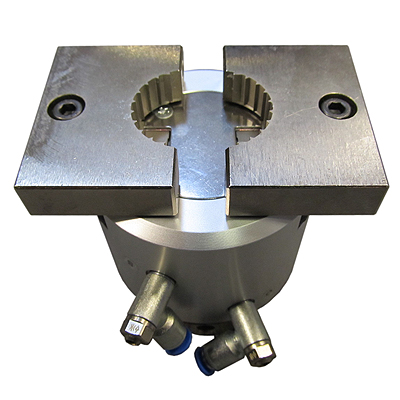

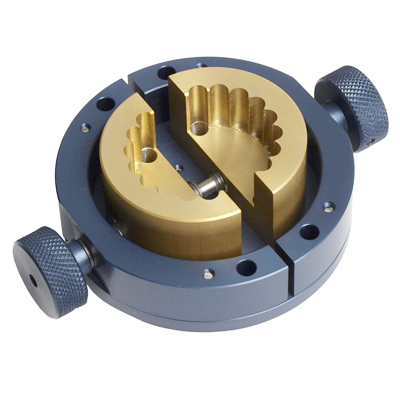

| Large saddle plate | Stelvin aluminium closure split mandrel, pneumatic | Split-mandrel cork grip | Upper keyless chuck, square drive |

| Lower keyless chuck, large, round shaft | Lower keyless chuck small | Pneumatic lift mechanism, Vortex | Dedicated moulded mandrels |

| Dust cover, MultiTest and Vortex | Torque reference bottle | Orbis and Tornado Mk II/Vortex torque cell accuracy check rig | Stelvin aluminium closure split mandrel |

| Upper fixing plate | Custom closure mandrels | Custom closure split mandrels | CRC mandrel |

| V-jaw vice clamp, three jaws with quick lock and release lever for Orbis, Tornado, Vortex | V-jaw vice clamp, three jaws with screw adjustment for Orbis, Tornado, Vortex | Mandrel Peg Drive, 54 mm |

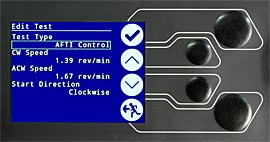

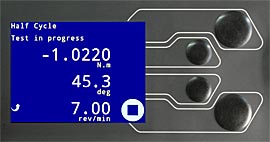

Clear, colour display, with continuous live readings, indication of status, rotational speed, angle, and (with AFTI connected) torque.

Clear, colour display, with continuous live readings, indication of status, rotational speed, angle, and (with AFTI connected) torque.