Error message

Warning: file_get_contents(http://ipinfo.io/3.17.154.9/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).USP 671 US Pharmacopeial Convention - General chapter <671> Containers - Performance Testing

Preparing samples for testing to USP 671

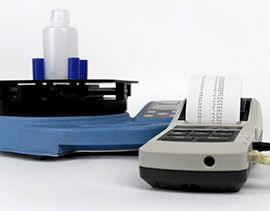

USP 671 provides standards for the functional properties of packaging systems used for pharmaceuticals and dietary supplements. Mecmesin torque testers or torque testing systems can be used to secure closures to the torque specified in the standard. The performance testing of the samples requires other apperatus not supplied by Mecmesin.

The test prescribes conditions for assessing the moisture vapour transmission of packaging systems used for solid oral dosage forms (SODF) and liquid oral dosage forms (LODF) for pharmaceutical and dietary supplements. Quantities of the containers are filled with dehydrated desiccant and the closure fitted and secured to a specified torque. Moisture vapour transmission is calculated by differential weight before and after storage in a humidity chamber

A calibrated manual torque meter capable of indicating clockwise and counter-clockwise torque capable of resolving reading to better than 5% of the nominal range of the measuring cell. Alternatively, a motorised torque measuring system is capable of delivering greatly increased repeatability and can be used to automate the testing, increasing throughput.

Select sufficient new, empty containers and clean the sealing surfaces with a lint-free cloth. For testing multiple-unit containers for Solid Oral Dosage Forms, close and open each screw-capped container 30 times, applying the torque specified in the standard.

Fill the containers with the specified quantity of anhydrous desiccant, and fit the closure to the torque specified in the standard. Table 2, below, specifies the cap application torque recommendations for screw type container closures—based on the closure diameter—for this performance test. The filled containers plus control specimens are weighted on a sensitive balance, then stored for the specified duration at the specified temperature and humidity. At the specified intervals, samples are removed from the humidity chamber, attemporated to ambient conditions, and weighed again. Calculations are made comparing the weight before and after the specified intervals with the control specimens

This overview is intended to provide a basic understanding of the test procedure and suitable equipment to meet the standard. Please refer to the latest official USP Pharmacopeial Convertion website for more detailed information.

Table 2. Torque Applicable to Screw-Type Container

The following closure torque table indicates the cap application tightness range for testing the container performance.

| Closure Diametera (mm) |

Suggested Tightness Range with Manually Applied Torqueb (in lb) |

Suggested Tightness Range with Manually Applied Torqueb (N.m.) |

|---|---|---|

| 8 | 5 | 0.56 |

| 10 | 6 | 0.68 |

| 13 | 8 | 0.90 |

| 15 | 5-9 | 0.56-1.02 |

| 18 | 7-10 | 0.79–1.13 |

| 20 | 8–12 | 0.90–1.36 |

| 22 | 9–14 | 1.02–1.58 |

| 24 | 10–18 | 1.13–2.03 |

| 28 | 12–21 | 1.36–2.37 |

| 30 | 13–23 | 1.47–2.60 |

| 33 | 15–25 | 1.69–2.82 |

| 38 | 17–26 | 1.92–2.94 |

| 43 | 17–27 | 1.92–3.05 |

| 48 | 19–30 | 2.15–3.39 |

| 53 | 21–36 | 2.37–4.07 |

| 58 | 23-40 | 2.60–4.52 |

| 63 | 25–43 | 2.82–4.86 |

| 66 | 26–45 | 2.94–5.08 |

| 70 | 28–50 | 3.16–5.65 |

| 83 | 32–65 | 3.62–7.35 |

| 86 | 40–65 | 4.52–7.35 |

| 89 | 40–70 | 4.52–7.91 |

| 100 | 45–70 | 5.09–7.91 |

| 110 | 45–70 | 5.09–7.91 |

| 120 | 55–95 | 6.22–10.74 |

| 132 | 60–95 | 6.78–10.74 |

a. The torque designated for the next larger closure diameter is to be applied in testing containers having a closure diameter intermediate to the diameters listed.

b A suitable apparatus is available from SecurePak, PO Box 905, Maumee, Ohio 43552-0905; www.secure-pak.com.

MRA Model with indicators on both the removal and application sides available in the following ranges:

1) 0–25 inch lbs., read in 1-inch lb. increments,

2) 0–50 inch lbs., read in 2-inch lb. increments, and

3) 0–100 inch lbs., read in 5-inch lb. increments.

For further detail regarding instructions, reference may be made to “Standard Test Method for Application and Removal Torque of Threaded or Lug-Style Closures” ASTM Method D3198, published by the ASTM International, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA 19428-2959.

Contact Mecmesin

Got a question about this product?

Our technical sales engineers can help find the right solution for your testing requirements and provide online equipment demos with your samples.