Error message

Warning: file_get_contents(http://ipinfo.io/18.191.176.115/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 656 of /home/closuretesting/public_html/sites/default/settings.php).Specification

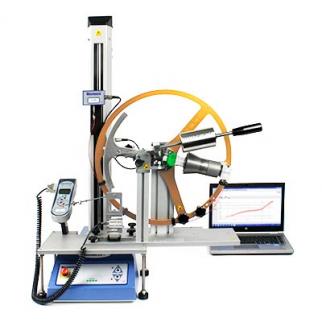

The rotational force needed to remove the closure spout from a sports cap body is measured using the Steinfurth Rotation Tester for Sport Closures mounted on a Mecmesin tensile tester. This ISBT test simulates a person biting or pulling on the spout when attached to a PET preform and requires specific tensile test equipment to meet the standard.

The International Society of Beverage Technologists (ISBT) publish voluntary codes of practice for the technical and scientific aspects of soft drinks and beverages. Their packaging guidelines include Sports Closures: Voluntary Standard Performance Specifications and Test Methods; indicating test procedures for the unique push/pull or twist-to-open spout closure design used on mineral water and sports drinks caps. The purpose of the Section 2.2 Rotational Test is to simulate a person biting or pulling on the spout of the closure to determine if the spout or any part will break, split or detach which could cause a potential choking hazard. The rotational force needed to remove the spout from the closure body is measured and compared to the acceptable minimum value of 5 N.

Solution

The ISBT sports closure rotational test stipulates the test equipment needed to perform the procedure; a tensile tester to apply load and measure the break force, a force gauge to measure the clamping force, and the specific bite clamp and rotational test fixture to grip the preform and spout. The Steinfurth Rotation Tester for Sports Closures (RSTC) includes all of the required elements to test an industry standard beverage bottle preform with closure. The RSTC includes a rotational wheel fixture that transfers the constant 300 mm/min axial motion of the Mecmesin test stand's crosshead into the combined rotational / pull-off force typical of how a person opens the spout. An initial pre-load of 50 N is applied to the bite-clamp mechanism, measured by a loadcell connected to a Mecmesin AFTI force gauge. EmperorTM software graphically plots the force characteristics and records the break load comparing it to the performance specification of the ISBT standard to establish a pass/fail result.